Today’s alcohol beverage industry has the world at its fingertips, giving producers everything they need to create a unique brand. And while many opt for traditional, time-tested methods (think barrel aging), there are plenty of others opting for less expensive and more sustainable techniques. Think about it: Oak forests won’t last forever if the trees are being used too young, and it’s virtually impossible to come up with a great-tasting $15 bottle of wine without pulling out a few tricks along the way. Luckily, the world is filled with creative people who get everything they can out of a single tree—and their efforts have resulted in high-quality products that look and taste fantastic.

GET INTO SHAPE

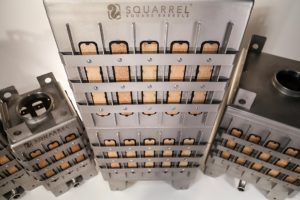

Russ Karasch says he’s been “making sawdust” (that is, woodworking) his entire career. He’s been a cooper for the past 31 years. He’s also a serial inventor: You can credit him for the wood infusion spiral, the honey comb insert, the grooved barrel—and now the Squarrel. One of his missions, when it comes to his work, is to address any cooper’s biggest problem: the shortage of oak trees. What he’s created in doing so has brought a new world of creative tools to the alcohol beverage industry.

“We’ve [given producers] an arsenal to get flavors that weren’t previously obtainable.” —Russ Karasch, Squarrel

Squarrels are just as they sound: a virtual wooden barrel with a reusable, square steel frame that’s built to house customizable staves. Launched in 2019, they range in size from 10 to 60 gallons. They’re mostly popular with beer and spirits producers, and were introduced to the wine industry in January 2020.

“The staves are the same as are used for traditional barrels, but they’re cross-cut to thin them and to gain microoxygenation,” he says. “Maturation takes less than a year, and will continually improve the longer the product is kept in the Squarrel. A lot of people end up with something they can sell in six to eight months, and you can get an extremely good product if you wait a year before bottling.”

Creativity is also key. “You can have different types of oak [and other wood, including South American umbriana] and levels of toast on each stave,” says Karasch. “Customers love the ability to be creative. Their goal is to never stop improving their product. What we’ve done gives them an arsenal to get flavors that weren’t previously obtainable.”

Cost and sustainability are also key. “You’d be lucky to get three traditional barrels out of one 125-year-old tree, which would equate to 200 gallons of liquid,” he says. “With a Squarrel, you can get thousands of gallons out of that same tree, because so much more of it is used. You have everything a traditional barrel can do but with more versatility, space and shipping savings [they’re stackable and less expensive to transport], and cost savings.”

“One oak tree harvested by StaVin can provide the equivalent of 500 barrels worth of oak products [as opposed to only five traditional barrels from that same tree].” —Alan Sullivan, StaVin [Photo: The StaVin toasting room; photo by Houman Pirdavari]

EXPRESS YOURSELF

Brothers Alan and Steve Sullivan launched StaVin in 1990 to provide winemakers with high-quality, traditionally fire-toasted oak products that duplicate what barrels give them at a savings of 90 percent. StaVin has since developed a wide range of products for tank and barrel aging, all created from sustainably sourced, carefully chosen forests in France, Hungary, and the United States. All wood is seasoned naturally for three years, which lets the indigenous natural microflora and natural elements soften the tannins before being thoroughly tested to prevent TCA, and then toasted.

“Seasoning the wood softens the tannins without removing them completely,” says Alan. “When toasted, the ‘nostalgic’ flavors are enhanced.” (Sullivan says everything you smell and taste is dictated by your olfactory bulb.)

The company offers fire or oven toasting and can mimic a multitude of barrel profiles. It also practices sustainability on several levels. “We have the only wet electrostatic scrubber in the wine industry,” says Sullivan. “The only thing coming out of our production facility is aromas. And we try not to waste any product. For example, one oak tree harvested by StaVin can provide the equivalent of 500 barrels worth of oak products [as opposed to only five traditional barrels from that same tree].”

Most recently, the company introduced Express Oak, a liquid tannin product that’s made from French oak and is intended as a finishing tool. “For example, if a wine doesn’t have enough oak extraction from traditional aging, Express Oak is an instant fix. It’s perfect for the winemaker who needs a fast touch-up just prior to bottling,” says Sullivan.

“StaVin’s Dr. Jeff McCord and Dr. Jeff Murrell spent five years in a custom-built laboratory to create it,” he adds. “It isn’t meant to replace other oak products, and works faster than chips or dust while delivering a much higher quality oak profile—with 100 percent natural ingredients.” The product has been on the market since late 2019 and has a level of 28° Brix.

“The wine industry is our main customer base, but the product can also be used with spirits such as brandy, and can turn a blanco tequila into an añejo in seconds,” he adds. Used in wine, small amounts of Express Oak make no discernable difference in color, even in white wine. “Most of our customers are producing wines that retail from $10 to $40. Why not over-deliver and make it taste like something that costs twice as much? Quality doesn’t need to cost a fortune.”

SPICE IT UP

Oak Solutions Group provides a wide range of products with its ēvOAK (oak adjuncts) and trü/tan (powder and liquid tannins) product lines. Its focus is on technology, innovation, and going beyond expectations with specialization. In 2019, it introduced its ēvOAK “High Proof Series,” which is aimed at the spirits industry but has also made a mark among winemakers.

In 2019, Oak Solutions Group introduced its ēvOAK “High Proof Series,” which is aimed at the spirits industry but has also made a mark among winemakers. (Pictured: Kyle Sullivan)

“We use a variety of different toasting technologies and levels to make products that fit within the alcohol beverage industry’s aromatic standards,” says Kyle Sullivan, global managing director.

The series has four different tank stave styles. “Spirits producers lean toward ‘Char Barrel,’ which mimics a freshly charred whiskey barrel. The staves provide lactones that are associated with whiskey, and some enhanced esters from the char. It also has fruity flavors and is in trials at some wineries,” says Sullivan.

Popular with both spirits and beer is ‘Rickhouse,’ which Sullivan explains as “fresh oak character that emulates what you smell when you walk into a rickhouse. It has that new oak barrel aroma.”

“Sweet Shoppe” appeals mostly to wineries and breweries. “The oak is toasted to get caramelized sugar and vanilla characters,” he says. “It’s a sweetness you’d expect to get out of bourbon.”

Finally, “Spice Rack” appeals to all three. “It has darker spice characters, such as clove and cinnamon, which pair especially well with rye products, because it intensifies their spiciness. With wine such as zinfandel and chardonnay, it enhances baking spice characters,” he says.

Sullivan notes the company is also working on some new chip, stave, and tannin products, expected to be released late this year.

MAKE IT UNIQUE

Heidi Korb, co-owner of Black Swan Cooperage in Minnesota, says she’s been around barrels her whole life. Full disclosure: Russ Karasch is her father. When Korb graduated college in 2009, Karasch helped her start up Black Swan, now trademarked “America’s Craft Cooperage.” Today, she co-owns it with partner Brian Lee and the company has 15 employees.

“Customers competing against larger companies can use our barrels to create a great product in a year or less.” —Heidi Korb, Black Swan Cooperage (pictured with her father and Squarrel creator Russ Karasach)

The cooperage is known for its wide variety of wood types as well as its patented Honey Comb inserts and cross-cut staves (yes, the ones Karasch invented). It offers white oak barrels from five to 56 gallons and almost countless flavor combinations with its Honey Comb inserts (which can be customized to fit any type of aging vessel, including tanks).

“A common question is why we only make barrels out of white oak. The answer is simple: It doesn’t leak—and it tastes good,” says Korb. “For example, cherry is very porous. Within a year, you could have up to 100 percent evaporation.

“My dad put cross-grooving on staves to open the end grain for faster extraction,” she adds. “Customers competing against larger companies can use our barrels to create a great product in a year or less.” The cooperage’s largest customer base is distillers, brewers, and hard cider makers. Its most popular choices for wood include hard maple, cherry, red oak, apple, and pecan.

MAKE A TOAST

Sometimes it’s the toasting style that seals the flavor deal. Formed in 1979, California-based Innerstave was the first to introduce stave inserts to the United States. Its newest product line is called Revere, which offers inserts, fans, cubes, and staves made of three-year seasoned French oak at three different toast levels. The products are unique because the wood is aged at the company’s Sonoma facility. “The microflora that grows on the wood as it ages is local, which sets the flavor apart,” says Carolyn Hillman, winemaker and sensory profile consultant for Innerstave.

“Aging for three years mellows out the tannins, creating a gentler, softer integration,” she adds, citing distilleries, breweries, cideries, and wineries as customers. “Distilleries like a higher toast with our French oak for finishing, which offers sweeter notes and a roundness that mimics longer aging periods,” she says.

The company is also testing two not-yet-announced products for the wine and spirits industries. At the same time, sustainability is one of Innerstave’s main goals. “American tree farmers have had it rough the last couple years,” says Hillman. “The trees used for wine barrels are 120 years old [or older] before they’re used, barrels for spirits use oak that’s as young as 80 years old. We want to ensure the tree supply remains available—each part has a purpose, and that’s how we’re giving back.”

Another California-based supplier is The Boswell Company, a long-time innovator when it comes to providing the United States with French and American oak barrels and French oak alternatives. It introduced silicone bungs in 1981 (now the industry standard), head toasting in 1987, and Jean-Christophe Varron’s Vinea oak alternatives in 2010.

“There’s still the impression that people think wines produced with oak alternatives are ‘less than.’ But that doesn’t have to be.” —Sean Adamowicz, The Boswell Company

Today, Jim Boswell’s daughter, Janice, along with her partner, Sean Adamowicz, and sales representative, Matthew Conrady, are in the process of taking the helm. Adamowicz prefers the term “enological wood” rather than “oak alternative” due to the quality of Vinea’s products.

“The past 10 years have shown the increased application and use of these products,” says Janice. “Not only in high-volume production facilities, but in more small- to medium-sized wineries looking to enhance their oak program. Whether the demand be retail price point, space limitations, budgets, or style preference, winemakers are looking for premium oak expression and finding it with Vinea, as the product is able to mimic the elegance and quality of a barrel.”

“Vinea was born from a belief that oak should not only be used for aromatic and flavor profiling, but should also bring elegant mouthfeel, body, and length to a wine,” says Adamowicz, noting Vinea sources the oak from premium center-of-France forests and ages it for 36 months prior to toasting—or “cooking” protocol.

“The ceramic elements can caramelize wood sugar without burning it by precisely controlling temperature.” Thus, the “cooking” analogy sometimes tossed around in discussion of Vinea wood. “This type of processing also lets the cooperage offer an oak product consistent in flavor and quality from vintage to vintage,” says Adamowicz.

“More than 1,000 winemakers in France use Vinea enological wood products,” Boswell adds. “There’s still the impression that people think wines produced with oak alternatives are ‘less than.’ But that doesn’t have to be. With oak products sourced from premium French oak forests and processed with such precise protocols, Vinea becomes an invaluable tool in closing the gap between tank/stave or barrel/insert and barrel finished wines.”