With so many small producers in the wine, beer, spirits, and cider markets, standing out from the crowd is top of mind. One way to do so is with shrink sleeve technology, which offers virtually unlimited creativity regarding graphics, look and feel. The biggest market for this has been craft beer, but other types of producers are discovering and employing it due to its suitability for small runs. Easiest for canned beverages, shrink sleeves are also suitable for glass bottles of any shape and size.

What is a shrink sleeve?

Shrink sleeves are a type of label that are printed onto flat film, cut to size, then placed into a heat tunnel that shrinks them onto containers. They offer 360-degree, high-resolution graphic capabilities as well as unlimited color combinations and texture styles including foils, matte or spot varnish and beyond. Within the alcohol beverage industry, they’re applied to empty cans or bottles, as heat would adversely affect the product in most cases. They’re especially attractive to those producing seasonal offerings or specialty, small-run items, as order minimums are much lower due to digital technology.

Creating a shrink sleeve label

The first step toward a successful shrink sleeve product is selecting a printer who understands its end use (container shape, type, application, contents) and who can guide you through graphic preparation to create a design best suited for your product. “[Sleeves] offer a versatile packaging option, as they can fit almost any container shape,” says Kristen Waite, marketing director for Hamilton, Ohio-based Innovative Labeling Solutions (ILS). “They’re common for craft breweries, but they’re also growing in popularity for wineries, distilleries, and household product markets.”

ILS began as a flexographic label printer in 1996, moved into the digital space for labels and flexible packaging in 2005, and began printing shrink sleeves in 2008. “Digital offers the most affordable way to customize packaging, because you can easily change graphics without a high minimum order requirement or up-front tooling costs,” says Waite. “It’s perfect for limited edition, specialty releases and for combatting inventory obsolescence. With sleeves, in particular, we were inspired by the opportunity to use 360-degree messaging, maximizing real estate at the retail shelf and increasing engagement between the consumer and the product.”

She continues, “[Sleeves] have to be designed correctly or the graphics can get distorted after application.” ILS clients interested in adopting the process are asked about particular needs, including container type and shape, as well as applicator requirements. “From there, the timeline is project-based. The process for standard sizes, like 12- and 16-ounce cans, is typically more streamlined, because we can use ready-made templates,” says Waite.

“For custom bottle sizes, we ask the client to mail us samples so we can determine sizing, material recommendations and provide a turnaround estimate based on project specifications. Then we print grid film and have it shrunk to the actual container. The results are used to develop an art template for the client’s designer to use.”

The idea is to enable print customization by knocking down barriers to entry, particularly for small and emerging brands. “It’s a way to bridge the gap between the digital and physical world,” says Waite, who emphasizes the importance of consulting with a printer to ensure specific needs are understood.

ILS doesn’t apply the labels, and most small brands don’t have the equipment to do so. Thus, application is often done by mobile canning operators.

Jim Cameron, national sales manager at MPI Label Systems (which has 11 manufacturing plants nationwide), also notes double-digit growth since the company started offering shrink sleeve services seven years ago. “Our decision to offer shrink sleeve services was customer-driven,” says Cameron. “They were looking at uniquely shaped containers and needed more flexibility for custom packaging.”

MPI’s largest customer base for beverage shrink sleeves is the wine industry, yet Cameron says the trend is taking off in the craft beer and cider markets as well. “When clients approach us, we discuss whether they’re new or established, and if their design agency can send us artwork to make sure we can execute the design.

“We also discuss graphic expectations of various treatments, such as cold foil, holographic patterns, gloss levels, or perhaps black-out labels [to cover other graphics that might already be on the containers]. We guide our customers through the entire process. One example is wine bottles. We collaborate during the design process to ensure design elements don’t fall into high shrink areas, such as the stem of the bottle, and cause distortion issues.”

“We also discuss graphic expectations of various treatments, such as cold foil, holographic patterns, gloss levels, or perhaps black-out labels [to cover other graphics that might already be on the containers]. We guide our customers through the entire process. One example is wine bottles. We collaborate during the design process to ensure design elements don’t fall into high shrink areas, such as the stem of the bottle, and cause distortion issues.”

Finally, he says, “The shape of the container dictates the design. We ask everyone where they want to be in two to five years so we can calculate the lowest possible price without sacrificing quality. In the end, it’s the appearance that’s the most important aspect regarding quality. It’s what makes consumers pick it up.”

Cameron adds if you’re considering purchasing equipment for applying shrink sleeves to wine bottles or aluminum cans, MPI recommends steam, because it provides uniform temperatures and better heat transfer.

Applying to Cans

David Racino, co-founder and CEO of Austin-based American Canning, started his company in 2012 as a mobile canning operation for beer. Today, it has three divisions: mobile (Texas only), equipment sales, and cans and supplies sales. “We focus on making the process affordable for small producers,” he says.

The company began applying shrink sleeves to cans about two years ago. “The client orders sleeved cans and we send a template to their designer, which includes requirements and tips for printing on cans,” says Racino. “Once the design template returns, it goes to prepress to create a PDF for approval. The shrink labels are printed on flat film that gets converted into a tube, then cut to size and placed on the cans. The shrink sleeving production line [label applicator and heat tunnel] can complete more than 230 shrink-sleeved cans per minute.”

He says the process takes about four to five weeks once the design is approved, so it’s popular not only for small runs but also larger ones because the turnaround is faster than traditional printed labels. Once the labels are applied, the cans are repacked and shipped to the beverage producer on specially protected pallets via a special partner to protect them from damage.

Racino says he’s also seen a growing client base surrounding canned spirits such as premixed cocktails, as well as wine and nonalcoholic beverages. The company also does promotional and seasonal cans as well as a lot of specialty cans for special events and music festivals.

Applying to Bottles

Applying to Bottles

Waterloo Container, based in upstate New York, is a family-owned glass bottle supplier with a goal of helping small to mid-sized producers grow their business through customization. The company has employed shrink sleeve technology for more than five years. “We purchased a high-speed applicator last year due to enormous growth,” says Bobbi Stebbins, marketing director. “Clients wanted to differentiate themselves, and we saw shrink sleeves as a way to create packaging that stands out on the shelf.”

Waterloo supplies the glass and shrink sleeve application, and otherwise works with clients’ designers to facilitate the sleeve process. “Shrink label cost may start out slightly more than paper labels, but the cost is equalized, since you gain valuable design space and remove the labor costs associated with paper labeling,” says Stebbins. “Things like holographic imagery, foil, cut outs, glitter and texture cost more, but those things appeal to the senses—and 85 percent of the time, if customers pick up a bottle, they’ll buy it.”

Because shrink sleeves are so popular now, Waterloo is adding a 37,000-square-foot building to increase production space. “It’s a substantial investment, but we know it’s worth it,” says Stebbins.

And since shrink sleeves work with any bottle shape, the possibilities are endless. “Another unique thing is, you can use a less expensive bottle and put a sleeve on it to make it look like colored glass,” she adds.

A Client’s Perspective

A Client’s Perspective

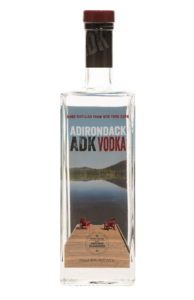

Adirondack Distilling in upstate New York employed shrink sleeves from the get-go when it opened in late 2012. The company produces vodka, gin, bourbon, and whiskey. “For our vodka and gin designs, we wanted something similar to Fiji water,” says Jordan Karp, distiller and co-owner. “But painting or screening that type of image onto the bottles was too expensive for our small company. We worked with Syracuse Label & Surround Printing and Waterloo Container to find a solution.

“Shrink sleeves were the answer for us,” he continues. “The art is striking and the turnaround was much quicker than we expected. We also like to keep things local, so it’s great that the companies we’re working with are so close by.”

Initial challenges included keeping the image from distorting on the company’s odd-shaped bottles. “We had to use reverse-curve text to get it to look right,” says Karp. “We also had to take steps to ensure national standards were met. Syracuse really helped with all that.” The result? The company’s shrink-sleeved products are expected to grow by double digits this year.

Possibilities and Growth

If you’re a new or established producer looking for small or seasonal/promotional runs, the shrink sleeve market is something to consider. It offers a quick way to create eye-catching graphics and multiple textures so products will stand out on the shelves — and its double-digit growth in popularity across the marketplace means the technology is here to stay.