Bottle closures—tops, caps, cages, corks, and the like—originally helped protect and preserve a bottle’s contents. Today, the materials and technologies to used manufacture these elements have been refined to the point that closures are as much a decorative packaging element as a functional one. “The closure of a bottle is a part of the whole design and the impact of a brand,” says Radi Necheva, office and sales manager for Herti US, the California-based arm of the Bulgarian closures company.

“An alternative closure can exude the idea of more luxury, celebration of a special event, or something different and emotional.” —Radi Necheva, Herti US

Popular spirits options include bar tops (also called shanks), screw caps, and t-top closures. Some distillers are opting for custom wood shells over a screw cap, an option that can be seen on some high-end tequilas. For beer, crown caps and pull crowns are longstanding popular options. The latter is favored for its ease of opening. Champagne-type closures, which feature a cork and wire-hood, are popular for Belgian-style and high-end beers, in part because they evoke an Old World feel.

Necheva says aluminum screw caps are a convenient product that maintains beverage quality and taste. They’re also recycleable, and younger consumers are demanding products with environmentally friendly, ethically sourced components.

Appearance is everything

A large part of consumer appeal is product appearance, especially in higher end items. “An alternative closure can exude the idea of more luxury, celebration of a special event, or something different and emotional,” Necheva says.

Interest in luxury closures, “is still growing,” says Paolo Ferrari, chief marketing officer at Guala Closures Group. “This trend has now extended to the wine industry, where producers pay major attention to their closures.” Consumers want their selections to not only protect the beverage but also “to look good,” he explains, adding, “The [packaging] needs to be more ‘Instagrammable.’”

[Image courtesy NimbleJack Partners]

Consumers touch and evaluate a spirits closure multiple times once they’ve made a purchase. “When the consumer has a [750 mL] spirit bottle at home, they usually touch the closure approximately 30 times, depending on the pour, before the bottle is empty,” says Heidenreich. “Every time the closure is touched, certain emotions are triggered. The liquid is almost secondary—at least initially.”

Creek Water Whiskey uses a swing-top closure. [Photo courtesy Next Century Spirits]

Although appearance may be the initial attraction, it’s key to remain product-first focused. Terry Borges, a sales product specialist for Saxco International, says, “If the package looks good and the product tastes bad, the consumer won’t come back.”

Untraditional corks

For producers intent on hewing to tradition, many technical advancements have been made to traditional closures, including in cork fabrication.

“There are natural inconsistencies associated with using cork. Diam became a high-value solution because we fix those inconsistencies.” —François Margot, Diam Bouchage SAS

“The challenge with cork is that it’s a natural material,” says François Margot, North American sales manager for Diam Bouchage SAS. “There are natural inconsistencies associated with using cork,” which can cause problems such as cork taint, off color in the beverage, random oxygen transfer and elasticity. “Diam became a high-value solution because we fix those inconsistencies.”

The company, which is distributed in North America by G3 Enterprises, developed a process in which natural cork is granulated, sorted, and treated using supercritical carbon dioxide to extract 150 unwanted molecule types, including those associated with cork taint. A binding agent and microspheres are then added to the clean cork granulate and molded with a special patented process to guarantee consistency, oxygen behavior, and mechanical performance of each Diam cork. Using these techniques, the company manufactures consistent cork closures tailored to clients’ targets, such as for lengthy or short-term aging, different oxygen needs, or pressure management inside a bottle of beer or sparkling wine.

The company sells only these micro-agglomerated corks, but has improved it such that it has the second greatest market share worldwide, including roughly a third of the champagne cork market.

Margot explains that having an improved cork product provides customers with a traditional image associated with particular beverages while also giving wine, beer, and spirit producers the choice, consistency, and reliability they need. (If you’re interested in learning more about natural cork, read “Top Choice.”)

[Near field communication chips are] “not only a packaging element, but also a media platform.” —Paolo Ferrari, Guala Closures

NFC adds information

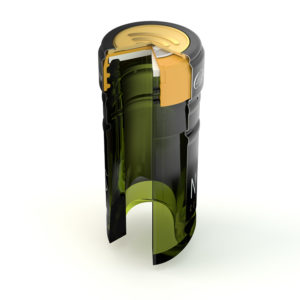

A novel addition to closures is near-field communication (NFC) technology, which lets two chip-enabled devices—in this case, a closure and a smartphone—connect wirelessly at short distances. NFC is perhaps best known for enabling digital wallet technology, but in a closure such as Guala Closure’s e-WAK, it becomes a digital marketing tool, says Ferrari. NFC technology lets brands launch dedicated loyalty programs, promotional content, virtual sommeliers, and many other custom features tied to consumption habits.

NFC also lets the producer track and trace each bottle once it leaves the production facility, which adds another layer of security for very high-end and collectible beverages.

The technology can afford a producer great flexibility in terms of messaging, including real-time adaptation in a pinch. For example, Jameson Irish Whisky, which uses the NĕSTGATE NFC closure, was able to shift its digital campaign immediately after COVID-19 lockdowns began in March. Rather than continuing to offer opportunities to win a visit to the Jameson distillery in Ireland by tapping the NFC closure, Ferrari says, Jameson instead began providing consumers with links to live masterclasses so they could make their own cocktails at home.

Inside an NFC closure [Image courtesy Guala Closures]

Closure costs vary but are strongly correlated with a beverage’s retail value. For spirits, says Heinreich, roughly 1 to 3 percent of a spirit’s bottle retail price is spent on a closure. Borges adds that some highly decorated bar tops can cost $20 each or more—but they’re typically only used for beverages that command $250 or more at retail. Wine closures—typically, natural cork—are roughly 1.5 to 2 percent of a still wine’s retail cost. Natural cork bar tops can cost between 10 to 50 percent more than synthetic shank bar tops.

Adding NFC to a closure makes “the final cost very high” says Ferrari. But, he qualifies, “we’re talking about the best technology available today. It’s going to be optimized in terms of cost when higher volumes will bring economy of scale.”

It’s “not only a packaging element, but also a media platform,” he continues. “Consumers interact with it both before purchase and during the whole product lifecycle once at home.” NFC, says Ferrari, is popular with those businesses that want to be on the leading edge of consumer interaction by doing something no one else in their space is currently doing.

Visuel Savin Prestige [Image courtesy Stavin]

“Even single-bottle hand application is an option.” If and when special equipment is needed, says Heinreich, Nimblejack helps producers finance the necessary equipment (contingent on the volume of closures being ordered annually).

Tiny bubbles

Closure choice can also depend on whether the tipple is carbonated. “It’s all about maintaining a proper seal to prevent unwanted oxygen exposure and/or fluids from being pushed out from back-pressure inside a bottle,” says Don J. Huffman, director of wine quality and sales North America for Vinventions USA. “Sparkling [beverages have] a couple of corks options: 100% cork bark, agglomerated cork—composed of cork and glue—plastic stoppers, and of course crown caps. In most cases, these beverages require a wire hood and that can add additional security to the closure. A traditional finished cork or even a standard screwcap cannot handle pressure of a sparking beverage.”

Crown caps, screwcaps, micro-agglomerated closures, and aluminum cans are all options for beverages with less than 3 to 4 bars of pressure, says Borges referring to the metric measurement for internal pressure. Sparkling wine, for example, typically has a minimum three bars of pressure. French Champagne is typically six (or more) bars.

[Photo courtesy Diam Bouchage]

In some instances “screw caps with specific liners can also be used for sparkling wines, carbonated water, or beer,” adds Necheva. Herti, for example, produces Saranex and Tin-saran screw cap closures that ensure air tightness and help control the oxygen transfer rate.

A closure poised for a relaunch in the U.S. market is the Zork SPK, a resealable closure designed for most carbonated beverages. [Photo courtesy Brick Packaging]

A closure poised for a relaunch in the U.S. market is the Zork SPK, a resealable closure designed for most carbonated beverages, says Papillon Erreca, general manager of Brick Packaging, which will be distributing the Australian closure in the North American market.

The closure consists of a button-seal to hold pressure, a foil gas barrier to prevent issues such as oxidation, a collet, and a locking cap. Once open, the consumer can depress the button into the cap such that the closure reseals. Erreca says it’s ideal for beverages consumers will want to enjoy some of now and re-seal for later, as it retains the carbonation in the bottle for several weeks. Yellow Tail Bubbles uses Zorks for all its sparkling wine production.

“For several years, the [Zork] closure wasn’t readily available in North America due to the lack of availability of the compatible bottle neck finish,” says Marc R. Kauffman, director for Novatwist Closures. “Now, however, several bottle producers are supplying the proper bottle.”

Ultimately, a producer must select a closure that both resonates with their target consumer and reflects their brand. Working closely with a knowledgeable supplier can refresh your brand, establish its personality, and attract the consumers you’re trying to reach.