[Courtesy Saverglass]

Popular choices

Popular direct-to-glass design options include screen printing, etching, frosting, painting, and powder coating, among others. Here’s what each of these processes entails.

“Our customers are thrilled with the ability to hold a decorated bottle sample in their hands within minutes of artwork approval.” — Scott Jost, Studio One Eleven

Just as it sounds, screen printing uses a screen (or a series of screens, one for each color in the design) to transfer ink or paint onto a bottle surface to create an image. Universal Packaging, which calls its screen printing process “applied ceramic labeling,” uses a photo process to translate an image into screens, which are then used to apply the design to bottles using ceramic paints. It may take a single pass or multiple passes for the front, back, shoulder, and neck to be fully decorated. “The [paint] essentially melds with the glass, creating the most durable bond of paint and glass,” explains Amelia Haselman, creative director of Universal Packaging.

“Screen printing offers design options that aren’t available—or that would be extremely difficult and/or more expensive than traditional paper labels,” says Caitriona Anderson, vice president of Monvera Glass Décor. “Screen printing companies can offer ceramic, precious metal, or UV inks.” These choices differ in how they’re cured after application. Ceramic inks require high temperatures akin to baking, while UV inks are cured using ultraviolet light. A more defining difference, says Anderson, is that “UV inks tend to be brighter, more vibrant, and have a less tactile feel.” She adds that UV inks also offer a broader color palette.

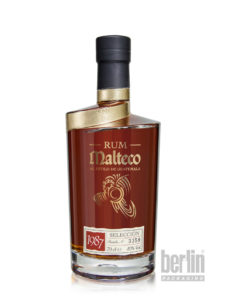

[Courtesy Studio One Eleven, Berlin Packaging]

He continues, “Not only can a UV printer apply photo-quality color artwork, it can also print gloss and matte varnishes and simulate frosting techniques. Our customers are thrilled with the ability to hold a decorated bottle sample in their hands within minutes of artwork approval. It reduces decision-making time, which gets their new package to store shelves faster than before.”

Screen printing can be applied alone or used in combination with other decorative processes. There are some limitations, however. Ceramic inks and precious metal screen print finishes can be used together, because both use high-temperature curing. But, as Maillet explains, “UV inks are less resistant and can’t be used in conjunction with metallic inks, as the high-temperature curing [needed for the metallic inks] would burn off the UV ink. When durability is a concern—for example, with a high-speed bottling line when bottle-to-bottle contact is likely to damage UV inks—use ceramic inks. Or, when the artwork also calls for metallic inks, use ceramic inks.”

Precious metal paints “are the ultimate material for high-end labeling,” says Haselman. Depending on the company, options include gold, silver, or copper paint. Rose gold is also growing in popularity.

“We’re always pushing the envelope and have come up with myriad printing innovations that sets our work apart within the industry and on retail shelves.” —Amelia Haselman, Universal Packaging

Etching, or cutting a design into glass, can be done mechanically or chemically. Mechanical etching is most often used for small-volume production runs, often in combination with hand painting. Within the wine industry, it’s typically reserved for 3-liter or greater volume bottles, because it’s a more costly option. Although it doesn’t offer traditional etching, Universal Packaging uses “etch paints” that can make a design appear as though it’s been cut into the glass.

Frosting is also known as acid-etching or chemical etching. In this process, explains Maillet, “glass is dipped in a bath of acid to create a matte, semi-transparent white finish. Acid-etching is durable but offers one color, one opacity, and one finish.” A frosted bottle looks like it’s just come out of the freezer. By treating portions of the bottle prior to frosting, it’s possible to put windows [of various shapes] in the frost. These clear areas let consumers see the bottle contents.

Powder coating is a finishing process in which a dry color base (in powder form) is affixed to a bottle via a chemical reaction. Either a portion or an entire bottle can be powder coated. The result can vary in color and opacity as well as finish, which can be glossy or matte.

Other, less common, decorative techniques are available as well. Sand blasting is a type of engraving that uses sand to make a deep, sharp designs—typically a name or logo—on the bottle. Metallization is a process used to fully coat a bottle with a high-sheen metallic coating that can also be colored. Hot foil stamping is an alternative to screen printing that delivers an eye-catching metallic element typically only to a portion of a design, such as a name or a logo; options often go beyond gold and platinum, including copper and rose gold.

Finally, hand-painting is an expensive option, best applied to limited-edition beverage releases. Typically, an artist is retained to both design and apply paint using the bottle as a canvas. As with anything created using the human touch, there may be slight variations from bottle to bottle. Some vendors use this in combination with other decorative methods.

Updating Brand Image

After paper labels, screen printing is among the most widely used bottle decorating techniques for adult beverage packaging, according to industry experts. “Screen printed and frosted bottles are a great way to ‘premiumize’ an existing brand,” says Steve Pelkey, president and CEO of Universal Packaging. “Consumers are willing to pay a higher price point for a brand that looks and feels ‘classy.’”

“We can create a visual simulation of a product, letting our customers envision their product in a real-world environment.” —Efrain Karchmer, Ardagh Group, Glass – North America

A brand that may be struggling or not growing might benefit from being freshened, while an established brand doing well in the market might take an “opportunity to create a ‘next tier’ or reserve-level brand that can be priced higher,” he continues. “At the very least, a positive brand ‘halo’ effect would occur and an existing brand would likely see some positive sales attributes. Unique packaging is a cost-effective way to compete against the giants.”

Mixing and matching media is another possibility. “Powder coating and glass frosting are both frequently requested in the spirits industry,” says Anderson. “These options are often combined with UV screen printing.”

Customers can have a one- or even two-color coated bottle. They can have it screen printed and later add paper labels or other materials, agrees Pelkey. “Thus, they can get a multi-medium approach to packaging, which is unique.”

Effectively decorated bottles also have significant shelf impact. Products at any price point can use screen printing, for example, to help their bottle stand out and make a positive consumer impression. Also worth noting: Decorated bottles hold up much better than those featuring traditional labeling, say experts; when in an ice bucket, for example, traditional labels may fade or soak off.

Design help

Some companies offer design and bottle production under one roof, but what happens when a bottle company needs to work with a specialty service provider? “When a winery, distillery, or brewery chooses to buy bottles and have them decorated by a third-party decorator, [the producer] takes on the coordination of the three-way process,” Maillet explains. “By working with a bottle manufacturer that also decorates its bottles, such as Saverglass, customers can not only save time and money, but also avoid logistical pitfalls that can sometimes turn into nightmares.”

[Courtesy Monvera Glass Décor]

Logistics execution depends on the vendors and the circumstances. Many bottle manufacturers have specialty service providers with which they work regularly and, thus, they can make referrals. “Sometimes the glass supplier itself is our customer; in that instance, the project is managed between us and a contact at the glass company,” says Anderson. In this situation, the glass company coordinates with Monvera Glass Décor on glass supply, delivery, deadlines, art approvals, and other details.

There are instances, Pelkey says, in which Universal Packaging works with beverage makers that supply their own glass. “We will work with the glass distributor and/or the customer directly to arrange for the glass to be shipped to us for decoration. We will then work directly with the winery, brewery, or distillery customer to deliver the decorated glass by their required date.”

Creative By Design

The process for creating a bottle embellishment varies depending on whether a beverage manufacturer already has a design. If not, those services can be available in-house at the bottle company or else one of the parties retains a graphic artist.

At Monvera Glass Décor, the customer typically submits a design, which is then evaluated to determine which printing machine is required to ensure the design will run efficiently in production.

Saverglass customers typically hire their own designer, with Saverglass providing technical advice. Together, they work through a two-step proofing process that concludes with the customer being given a fully decorated prototype bottle for approval. “This process can take anywhere from a few weeks to several months based on the intricacy of the decoration,” says Maillet.

Ardagh Group employs technology to its advantage, explains Efrain Karchmer, director of new product development and innovation for Ardagh Group, Glass – North America. Ideation sessions and consultation can take place remotely, and “Through our use of 3D modeling and professional renderings, we can create a visual simulation of a product, letting our customers envision their product in a real-world environment, including labels and bottle decoration, closures, and filled contents.”

[Dieter Kühl – DK Fotografie; courtesy Universal Packaging]

Most often, designs are based either on existing art or traditional paper labels that are redesigned for the screen printing process. “We’re always pushing the envelope and have come up with myriad printing innovations that sets our work apart within the industry and on retail shelves,” Haselman says. “In a nutshell, we really love what we do, we consider each bottle is a painted work of art, and our passion for beauty comes through in every design we work on.”

Cost Comparison

The cost of bottle decoration versus traditional paper labeling is competitive, but no two suppliers offer the same opinion. Typically, pricing is an “it depends” issue contingent on the materials, technique or techniques, size of the print run, and other issues.

Anderson says there’s a misconception that direct-to-glass decoration is “more expensive than it actually is, because it looks expensive.” She continues, “I’d encourage more people to explore the option. And remember, it’s not necessary to screen print all your labels.” Instead, she suggests, this type of decoration can be saved for specialty releases such as reserves, dessert wines, or commemorative releases.