Nothing demands portability like a pandemic.

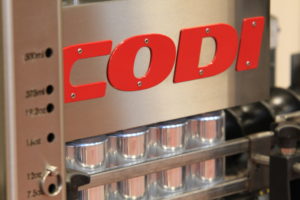

When restaurants, bars, and taprooms across the nation shut down in March in response to the novel corona virus, brewers were left sitting on tanks of beer, with no way of getting it into their customers’ hands. In response, Codi Manufacturing stepped in to help craft brewers in the Denver, Colo., area. Codi manufactures canning equipment, including lines suitable for small-scale breweries or limited runs of specialty beers. The equipment is compact, with a small footprint, easy to set up, and, because of its counter pressureure filling technology, it’s suitable for products from still to highly carbonated. Jared Jones, Codi’s chief operations officer, recognized that many craft breweries live primarily by sales out of their taprooms, so he quickly mobilized several canning lines.

“We’re offering [the lines] at no cost to local breweries that are stuck with liquid in their tanks, because they were shut off with only 24 hours notice,” he said in mid-March, after Colorado Governor Jared Polis issued the shut-down order. “We started this morning. By this evening, we’ll have three machines ready to go, able to can product as needed. The [breweries] can then take that product and sell it. We’re helping them preserve their business, not just their product.”

“My dad and my uncle identified the opportunity for canning early on.” —Russell Love, Cask Global Canning

Craft in Cans

Beer in cans is nothing new, but for craft brewers it’s something of an innovation. And the popularity is skyrocketing. Consumers love cans because they’re lightweight, portable, and sustainable. The lighter weight (compared to bottles) also means significant savings on shipping costs for producers. And cans offer protection from light while also providing a better seal than bottle caps, keeping oxygen away from the contents.

Alberta, Canada-based Cask Global Canning Solutions pioneered microcanning in 2002. “My dad and my uncle identified the opportunity for canning early on,” says Russell Love, who took over leadership of the company as president in 2018. His father, Pete, began the business in 1982, selling brewing equipment to home brewers across the United States and Canada. As more and more customers requested canning equipment, Pete and his brother built their first system. Love remembers it was, “just a little table-top manual canning system that would do maybe eight or 10 cans per minute. It was the predecessor to the much improved MCS that we’re still selling to dozens of small breweries each year.”

Oskar Blues Brewery was the first customer. Within a few years, as sales exploded, the Denver brewery and pub began requesting a bigger automated machine. Cask delivered and, by 2008, Love says, Cask’s business started to take off. Cask now manufactures five different automated canning lines, with capacities from 10 cans per minute up to 100 cans per minute, serving clients in 60 different countries around the world. The cost per machine ranges from just below $20,000 to $185,000 (USD) for base systems.

“It’s been a long trend over 20 years of zero percent craft beers in a can to just over 50 percent last year,” Love laughs. “That’s a trend we’re super proud of having created!” These days, the opportunities extend well beyond beer.

There are plenty of beverage producers other than craft breweries looking for agile canning systems. Today’s market is flooded with canned wines, ciders, seltzers, and ready-to-drink cocktails, as well as innovative drinks like kombucha and cold-brew coffee. Canning manufacturers have responded with innovative equipment.

“We’ve spent lots of time in the last 10 years focusing on really squeezing the last molecule of oxygen out of the can and optimizing our systems to reduce loss across a wide range of beer types and carbonation levels,” says Love. “A brewery will hopefully be able to hit, with training from us, less than 20 parts per billion of oxygen pick-up, and have somewhere less than 1 to 2 percent of product loss.

“We were the first people to ever put a tank below the fill head.” —Jared Jones, Codi Manufacturing

“Every percent of product lost is a dollar not in the bank, and every little bit of oxygen in the can is a reduction in shelf life—an oxidized beer somewhere down the road—and that doesn’t serve anyone in the industry.”

Love’s team is at work on more than a dozen other innovations to make their equipment more bespoke for specific industries, he says, including including a multi-stage rinsing process for a large kombucha producer that virtually guarantees bacteria-free cans.

Codi Manufacturing has also made contributions to the science of canning. The company’s biggest innovation, says Jones, is “the world’s first inline counter-pressure filler and mechanical based seamer. We were the first people to ever put a tank below the fill head.” He explains the system is a scaled-down form of the technology found in higher-speed applications used by mega-producers like Anheuser Busch, which allow extremely fast filling. Codi also supplies equipment for a complete canning system, including depalletizers, twist rinsers, and conveyors.

Custom Cans

“It’s a clean new package every time, so you’re not worried about having to clean out a growler.” —Mike Murfitt, Crowler Nation

Innovations are also popping up in aluminum vessels themselves. Crowler Nation, based in Longmont, Colo., offers infinitely recyclable 32-ounce and 25.4-ounce aluminum cans, with a bar-top seamer, as an alternative to a glass growler. “It’s a clean new package every time, so you’re not worried about having to clean out a growler,” explains Marketing Director Mike Murfitt. The company has also developed a pre-seamed growler with a twist-on top. That product led to a spin-off sister company called Twistee Cans, marketing pre-seamed crowlers in eight different sizes.

In a sense, cans create their own market. John Wilkinson, CEO of Napa-based custom-crush company Bin to Bottle, says a new client recently contacted his group for help with a start-up wine business, to be exclusively marketed in cans—no bottles.

Since it started 15 years ago, Bin to Bottle has grown to produce, as well as package, a variety of drinks besides wine, including white and brown spirits, cider, and cocktails. The group invested in a canning line in 2019, capable of 65 cans per minute, and is adding another this year with double that capacity. Canning is just one of the many services they offer, but the boom in canning has helped to grow the adult beverage production business, which is housed in a completely separate facility. Bin to Bottle is ramping up both the packaging operation and the alternative beverage production to be a separately branded part of the business. Its core winery business will continue to grow as well, in its separate, state-of-the-art winery.

Bin to Bottle invested in a canning line in 2019, capable of 65 cans per minute, and is adding another this year with double that capacity.

Wilkinson recalls another client who made a wine cocktail called Gaze, packaged in a distinct bottle-shaped aluminum can with an ROPP screw cap. “We did 60,000 or 70,000 cases of that product,” he says. “One of the main drivers of that project was the package itself. Our client just loved that package. They wanted it in that specific can. Obviously, the beverage was important, too, but there’s no question the can itself was a big part of the sale.”

Sonoma, Calif.-based Free Flow Wines, launched in 2009, provides keg leasing, filling and logistics services to wineries using 100 percent reusable steel wine kegs that simplify on-premise sales of wine by the glass—popular in venues like restaurants, sports arenas, and music festivals. Free Flow owns the kegs and manages all return logistics, cleaning, and filling, so the wineries can simply ship and forget. The company added single-serving aluminum can filling services three years ago.

“A number of our clients were interested in the up-and-coming canning category, so we put in a small line in April 2017,” says Heather Clauss, chief commercial officer. “From that point on the demand for our canning services has been so excessive that we now have three of those lines in place, along with a new fully automated high-speed line that fills 300 cans per minute.”

Clauss says the demand is largely driven by the eco-conscious millennial market, as well as expanded use occasions (including camping and outdoor events). “With [wine in] kegs, quality and sustainability are the key benefits. With reusable packaging, nothing is going to the landfill, so you’re greatly improving the carbon footprint of the wines,” she explains.

“A number of our clients were interested in the up-and-coming canning category, so we put in a small line in April 2017.” —Heather Clauss, Free Flow Wines

“You can’t get a keg of wine at your house, but we felt cans were the most compelling alternative to that. They’re aluminum, which is the most highly recyclable packaging available. You can throw a can into the recycling bin today and it will be a new can in an average of 60 days.”

Can Creativity

Boutique wineries have always relied on mobile bottlers, so as the market for canned wines grows, it’s only natural to see mobile canners appear on the scene. Nathan Ofstad and his wife, Jamie, launched Tinman Canning three years ago in Oregon, adapting the technology from beer canning lines to meet the needs of wineries and other beverage makers in Oregon and Washington. “Even though wine is our specialty, we do a lot of canned cocktails, beer, and other beverages as well. Our portfolio is pretty diverse,” says Ofstad.

“Our lines have the option to use heat and steam sanitization rather than chemicals. That’s important, depending on which beverage you’re canning, especially wine,” he says.

Tinman just rolled out customized in-line carbonation, adding various levels of fizz to canned drinks and giving winemakers a new level of creativity.

“Even though wine is our specialty, we do a lot of canned cocktails, beer, and other beverages as well. Our portfolio is pretty diverse.” —Nathan Ofstad, Tinman Canning

“We’ve been seeing a lot of growth in sparkling wine—sangrias, spritzers, blended beverages that are still wine-based,” Ofstad says. “A lot of our customers are finding it fun to play around with. They can do lighter carbonation to create more of a spritzer, and it will taste completely different than if they added full carbonation and created a true sparkling wine. It changes the taste, the mouth feel—everything about that beverage changes.”

A Classic in Cans

A move into aluminum cans could result in more than just new flavors. At Tivoli Brewing in Denver, it’s part of a whole new branding campaign.

CEO Ken Hehir took over the iconic brewery in 2018 (Tivoli is the oldest brewery in Colorado, founded in 1859, preceding Coors by 14 years), and launched a complete rebranding with a new logo and new color schemes. Tivoli’s historic brewery is located on Denver’s Auraria Campus, home of the Metropolitan State University of Denver, and Cask Global Canning had donated a canning line to the school’s brewing program.

“The thing about a can line like that is, we can fire it up and do 10 cases of something. If we need to fill sample cans for our sales team, we can fill five or 10 cases for them, no problem, at all. It lets us remain flexible,” says Hehir.

“Our hope was that, with the right packaging and the right beers, we’d sell more packaged product. And it actually worked out that way.” —Ken Hehir, Tivoli Brewing [Photo: Tivoli Tap Room]

The move to aluminum has paid off handsomely, Hehir says. “When we started this process, more than a year ago, 80 percent of our sales were draft beer. We skewed heavily draft and on-premise. It’s probably more of a 60-40 split now. Our package growth has been at a much higher rate than our draft growth. In general, our package sales—April through the end of the year—that number is north of 70 percent growth over what bottles did.

“Our hope was that, with the right packaging and the right beers, we’d sell more packaged product. And it actually worked out that way,” he says. “It was a strategic move, but it was definitely the right thing to do.”