Bottle closures probably aren’t the sexiest part of spirits, wine, cider, or beer packaging, but they’re integral to the quality of what’s inside. And while many producers swear by natural cork alone, there are all kinds of other options for those who want to explore the world of alternatives that can keep their beverages safe inside their vessels.

Spirited reached out to closure producers to get a closer look at what goes on in their world, and what’s new or on the horizon.

Guala Closures Group

“Continuation of innovation has been the key to Guala Closures’ success.” —Violette Montagnese, GUala Closure

Guala Closures Group was founded by two brothers in 1954, right around the time Nobel Prize winner Giulio Natta was developing the process that led to the invention of polypropylene. “In these early years, the brothers invented the safety closure, which made it far more difficult to counterfeit alcoholic products,” says Violette Montagnese, who is in charge of group marketing at the company’s headquarters in Luxembourg. The Guala brothers’ ongoing innovations led the company to expand into wider European markets. In 1998, ownership passed to a group of entrepreneurs chaired by the current president, Marco Giovannini. “Today, [Guala Closures] products are sold in 100 countries, supported by five research centers—one of which is entirely dedicated to technological innovation—30 production plants, and more than 4,700 employees,” says Montagnese.

“Continuation of innovation has been the key to Guala Closures’ success,” she continues. “The company is continually exploring new materials and solutions, which means adding to the historic line of safety closures, aluminum screwcaps, luxury and, more recently, ‘connected’ and sustainable closures.

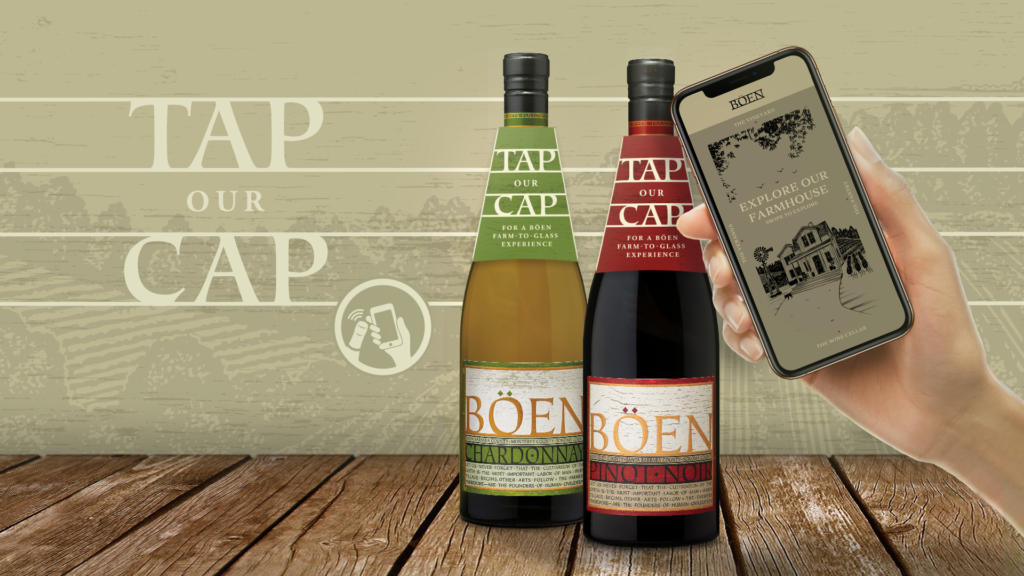

“A good example of a highly innovative product resulting from our R&D program is the NěSTGATE range of ‘connected‘ closures, which use Near Field Communication [NFC] and QR codes. These are the latest development for all major markets. [It’s] the result of our understanding that consumers want more information about the product they’re buying and brands want a closer and deeper relationship with—and understanding of—their customers.

“Launched in 2019, NěSTGATE has revolutionized conventional bottle packaging by integrating this connectivity feature into the closure,” says Montagnese. “Consumers can tap the closure with their smartphone and engage with the brand on a number of levels. Features include anti-counterfeiting tools from unique serialized IDs to blockchain systems, while the track-and-trace technology records the entire product journey.

Blossom closure [Courtesy Guala Closures]

The company is also investing heavily in sustainability efforts, which encompass systems to help its employees, business, and the planet. “The group intends to achieve the challenging objective of using 35 percent recycled materials across its entire product range by 2025,” says Montagnese. Its Blossom range of sustainable closures was launched November 26, 2020.

In addition, Guala remains focused on research and development activities, in particular those centered around sustainability. “Responding to customer needs and sustainability issues are the inspiration for innovation in our products and processes,” says Montagnese.

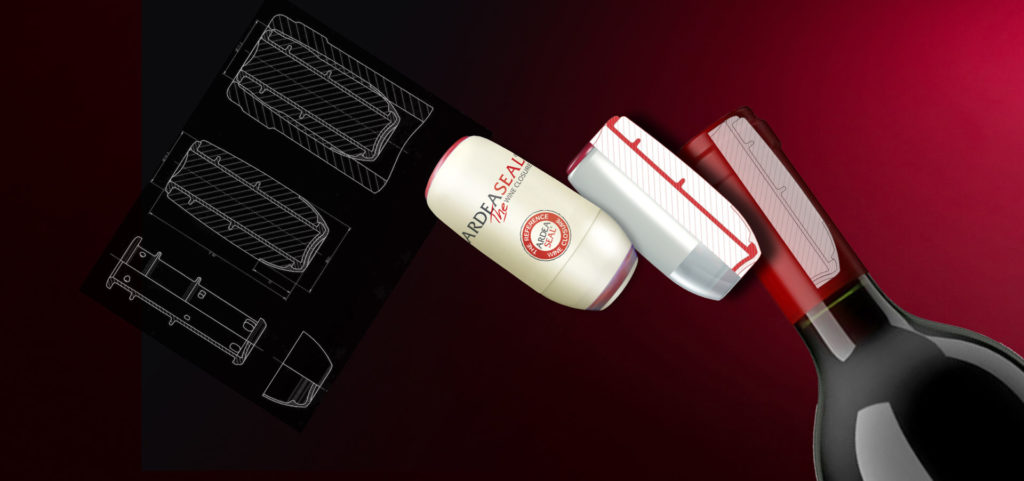

ArdeaSeal

The ArdeaSeal wine closure has been on the market for roughly 20 years. Originally founded as Guala Seal, in about 2015 it rebranded as the ArdeaSeal wine closure. Located in Tortona, Italy, the now French-owned company has expanded within Europe and abroad.

“ArdeaSeal’s carbon footprint is less than screw caps and other synthetic corks.” Paolo Bouchard, ArdaSeal

“The closure is made of three parts: The chassis helps maintain structure, rigidity, and elasticity; the body gives the closure its shape and is what the corkscrew punctures through; and the shield, which is made of the same completely inert polymer found in pacemakers, is what dictates the oxygen transfer rate [OTR]. It’s what lets the wine, spirit, or beer breathe at the same consistent rate,” says Paolo Bouchard, business development manager.

“Since the closure provides a 100 percent consistent and reproducible OTR, you will never have problems related to TCA,” he adds. “It’s a synthetic closure, but due to the experience of removing it with a corkscrew—like with natural cork—and by it making a popping sound, it truly has a premium feel and look to it.

“The ultimate tests, however, are the results in the producers’ cellars,” he continues. “After 20 years of experience, wines closed under ArdeaSeal remain ‘net’ and without any problems of TCA, organoleptic deviations, or oxidation problems.

“In terms of production,” says Bouchard, “ArdeaSeal’s carbon footprint is less than screw caps and other synthetic corks, but slightly higher than natural cork. Because of the closure’s unique design, more than 75 percent of ArdeaSeal customers do not use foils, which have a very high carbon footprint and serve no real purpose besides being aesthetic.”

[Courtesy ArdaSeal]

“Producers in Bordeaux—such as Château Croix de Labrie and Clos Manou, Matthieu Barret from Domaine du Coulet in Cornas, François Carillon in Puligny Montrachet, or Laurent Ponsot in Morey St. Denis—are vouching for ArdeaSeal because it lets them, on a consistent basis, protect and deliver the potential of all their hard work in their vineyards,” says Bouchard.

Herti

Bulgaria-based Herti was founded in 1993 by three entrepreneurs looking to produce aluminum screw caps for vodka and brandy. There was no such producer in Bulgaria at the time. The company started with one machine that could produce two sizes of screw caps for spirits, as well as 10 workers. Today, Herti is a public company producing 40 sizes of screw caps with almost 500 employees. It sells its products in more than 50 countries worldwide and has subsidiaries in the United Kingdom, United States, France, Germany, and Romania.

“Herti manufactures almost any possible dimension of aluminum closures.” —Radi Necheva, Herti

“Herti manufactures almost any possible dimension of aluminum closures and suggests packaging solutions to clients producing wine, spirits, and more,” says Radi Necheva, sales manager. “We offer closures varying from 17 to 43 mm in diameter, and 12 to 60 mm in height. They’re used for sealing bottles with various capacities starting from 50 mL to a gallon (4.54 L). Customers may choose from different design options: up to five colors offset printing, matte, semi-matte and glossy finish, hot- foil printing, embossing, and top-relief. We also produce composite closures, a highly successful combination of an aluminum body with a plastic insert designed to provide safety and elegance to the bottle,” she adds.

Necheva says what separates Herti from others is its focus on the customer. “Herti invests constantly and continuously in the latest production technologies and organizational improvements to guarantee its clients the best service and the highest quality of products. What we do differently is our exceptional service and optimal timing. We build mutual partnerships and maintain continuous contact with every client, keeping our promises,” says Necheva.

[Courtesy Herti]

“Our research and development department has optimized tooling instruments, which leads to lower consumption of aluminum and energy, and decreases production waste. We also moved to an adiabatic cooling system in the production facilities, which helps save energy and water.

“For the last period examined, we had an almost 40 percent decrease in CO2 output,” she adds.

Moving forward, “We’re working on a project for implementing an innovative printing technology that will significantly reduce the printing process and decrease energy consumption.”

Mala Closure Systems, Inc.

In 1992, Mala Closure Systems was founded in Germany by Andreas Lange and his father to provide innovative and high-quality closures for the wine and spirits industries. The company developed proprietary equipment and quickly grew to a top position in the screw cap industry.

“As a family business, the company was guided by its founders to expand internationally and founded a sales representation in Northern California that I built and managed from the beginning,” says Gisela Cartwright, senior sales and administration manager. “In 2014, it became apparent that moving part of the production to a location close to the wine industry in Sonoma and Napa counties, the centers of U.S. wine growth, would reduce production times, delivery time, and increase customer satisfaction for wineries of all sizes,” she says. “In 2020, Mala Closure Systems became an independent company that can now focus even better on the U.S. market’s specific needs and provide additional products and features.

“Mala offers the quality and the flexibility to serve the wine and spirits industries with closures that reflect the creativity and unique qualities of the drinks and their makers,” says Cartwright. “The capability to deliver all size orders with the same commitment to quality and high-end customer service is where we see our place in the market.”

A big part of Mala’s business concerns aesthetics. “From the more than 70 standard colors—of which, a wide range is in stock for immediate delivery—to highly customized products, we deliver the visible quality of the color and the invisible quality that guarantees just the right closure for the beverage. Our closures are an integral part of the story that wineries are telling with their packaging: give joy, create memories, convey experiences,” she says.

“Every job is different. We have customers of all sizes and interests: Some order a container, some two boxes. We have clients who have worked with us for more than 10 years and reorder the closures they trust in quality and design; others are just getting into the beverage business or decided to switch to screw caps and appreciate the personal Mala touch. We explain the technology as well as the many design options available, provide color-matching to label colors or corporate identity, work with surface finishes including high-gloss, matte, and metallic. We’re also excited about the new design technologies we will offer in 2021,” says Cartwright.

Mala uses various liners to offer optimal sealing solutions for a wide range of beverages. “Depending on the beverage, the liner needs to have different physical qualities. Saranex liners, for example, offer oxygen permeability for controlled oxygen transfer and some aging in the long cap wine closures. Spirits with a high alcohol content require different closures and liners than wine.”

She continues, “The winemakers and distillers we work with create unique products in a long and often laborious process. They need to ensure the product they created arrives safely and in prime condition for the consumer. We put the closure to this process.”

Maybe closures are sexy after all.

SIDEBAR:

A World of Options

Aside from the companies closely profiled in this article, there are myriad other producers, all with their own unique capabilities. Here are some of them.

Enoplastic offers a wide variety of screw caps and synthetic corks. Some are created for “drink now” wines, while others offer the advantage of aging without the risk of TCA contamination.

Saxco focuses on the craft beer industry, offering metal and plastic closures, as well as plastic-topped natural cork and swing-top stoppers, all of which can be customized with colors, finishes, liners, and more, based on original package designs.

Vinventions has plant-based closures called Nomacorc. Made from sugar cane, they’re both customizable and recyclable. Wines under Nomacorc can be aged up to 25 years, without the risk of TCA contamination, and they’re easy to extract and reinsert.

Amcor has aluminum closures for spirits and wine, including a proprietary system called Shapeart, which can be used to create custom closure shapes to further enhance a product’s look.

Spirited Packaging has partnered with Cork Supply to offer a wide array of natural, technical, and synthetic corks and closures. Think of it as a one-stop shop for a wide range of options and ideas.